The post processing technology of wine box printing is the treatment after completion. Surface processing is to improve the beauty and quality of wine box packaging, mainly covering film, technology mainly have concave and convex embossing, die-cutting indentation and other processing technology

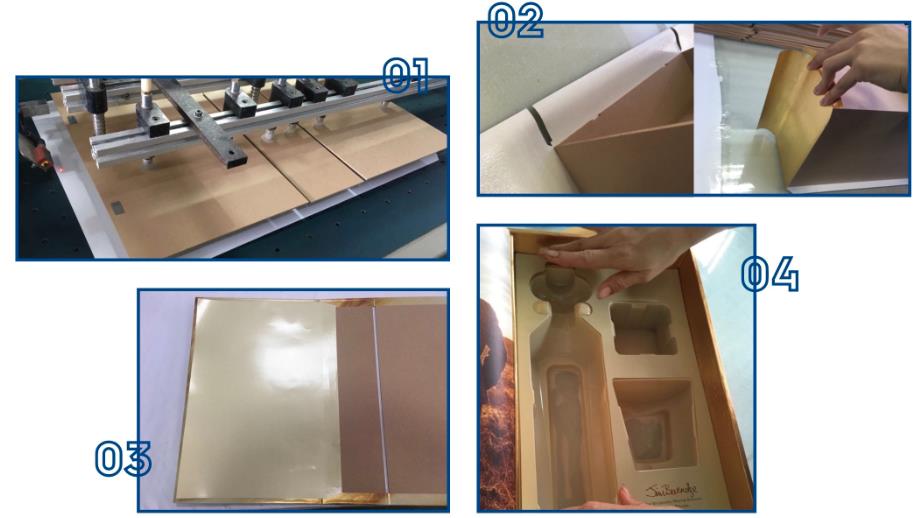

1.Film covering

Lamination is a kind of transparent plastic film which is pasted onto the surface of printed matter by hot pressing to make it more smooth and bright, and the color of pictures and texts is more bright. At the same time, it also plays a waterproof and antifouling role. It can be divided into two parts: surface processing and molding processing, hot stamping, polishing and waxing.Molding seed processing technology. Film covering makes the printing surface wear-resistant, folding resistant and chemical corrosion resistant. However, due to the non degradable plastic film, it is difficult to recycle and cause pollution. Therefore, in the case that glazing can be replaced, plastic lamination process should be used with caution.

2. Hot stamping

Hot stamping, also known as hot press printing, is to make the pattern or text to be hot stamping into a convex plate, and with the help of a certain pressure and temperature, various aluminum foils are printed on the substrate, showing a strong metallic light, so that the product has a high-grade texture.At the same time, due to the excellent physical and chemical properties of aluminum foil, it can protect the printed matter. Therefore, hot stamping process is widely used in modern packaging printing

3. Polishing and waxing

Glazing is to coat or spray a layer of colorless transparent coating on the surface of wine box printed products, brush the luster of the product, and play the role of waterproof and oil stain on the surface of wine packaging box. The product has bright luster and good barrier effect.To form a glossy film to increase printing wax is to apply hot-melt wax on wrapping paper.

4. Embossing

Concave convex embossing is a special method to decorate the surface of printed matter. It uses a concave convex mold, under a certain pressure, to make the printed material plastic deformation, and then to print the surface and art processing.All kinds of embossed graphics and patterns show different depth patterns, with obvious relief feeling, which increases the three-dimensional sense and artistic appeal of the printed matter.

5. Die cutting indentation

Die cutting indentation is also known as pressure cutting molding, button knife, etc. When the wine packaging printing carton needs to be cut into a certain shape, it can be completed by die cutting and indentation process. Die cutting is to arrange steel blades into a mold (or carve a mold with steel plate), frame, etc,In the process of cutting paper into a certain shape on the die-cutting machine, the hollow part of display surface in the middle is obtained by die-cutting technology, which becomes the personalized decoration in the whole package. Indentation use the steel wire, through imprinting on the paper out of traces or left for bending groove mark.

6. Gold stamping

Gold, silver, laser gold, bronze gold, etc., are generally gilded or silver only after gluing; there should be alignment line for film making; the stamping effect is various, but according to the base materials for stamping, it can be divided into gilding paper, flannelette and plastic.

7 Spot UV

Is a silk screen printing process, through the paper box surface graphics and text local coating UV varnish to enhance the color effect.

8. Freezing snow

The effect of freezing snowflake is the ink printing on gold card paper, silver card paper, laser card paper, PVC and other substrates after UV light wrinkling and UV curing. Because it appears as a thin layer of snow or ice on the surface of printed matter.Commonly known as "snowflake" (larger pattern) or "freezing point" (smaller pattern) in the industry. It is widely used in tobacco and wine boxes, calendars, gift boxes and other exquisite prints because of its fine patterns, strong three-dimensional sense, luxury and elegance

9. Reverse matting

Reverse matting process is a new printing process which appeared in the past one or two years. It needs several times of special primer or varnish treatment to complete; some people call it reverse glazing process, and regard it as a new process of local glazing. After printing according to normal color sequence, on the basis of ink drying or curing, offset printing line (or offline) is used to print a layer of special primer on the local area that does not need to highlight high brightness. After the primer is completely dried, the whole printed matter surface is coated with UV varnish in full plate mode.In this way, the cohesion reaction occurs in the area where the uvvarnish and the base oil contact, forming a small granular ink film, forming a matte or frosted rough surface; while in the unprinted UV glazing area, a high gloss mirror surface is formed. Finally, the printing surface formed local high gloss and local frosted low gloss area. Two completely different glossy effects achieve high contrast effect of local image, embellishment and highlight the image and text with glossy mirror.

10. Relief gold stamping

This process is through the change of bronzing plate, showing a strong metallization and three-dimensional feeling. Through the concave and convex changes of relief patterns, the graphics and texts present the texture of metal relief, which makes the bronzed graphics and texts jump out of the plane and bring stronger visual impact.

11. Laser transfer

It has a gorgeous visual effect and can effectively improve the level of packaging. The process can print full plate or local transparent laser effect on plain paper with smooth surface. It has changed the processing method that laser effect can only be displayed by laser paper printing or by compounding proprietary laser film on the paper surface. It can achieve flexible laser pattern

12. Photoresist

A kind of paper material with very high technical content integrates many advanced technologies, such as local embossing, holographic laser anti-counterfeiting, vacuum aluminum plating, paper plastic composite slitting and sleeve printing, which has changed the situation of single laser grain effect in the past. The gorgeous visual effect of paper is unique. In addition, it has unique anti-counterfeiting function, so it is not only impossible to copy , but also convenient for consumers to visually identify the truth.Websit:www.risunprint.com Contact: cathy Mobile / Whatsapp: +86 17875315636 Skype:+86 15626183287 Email: cathy@risun-print.com