Categories

Recent Posts

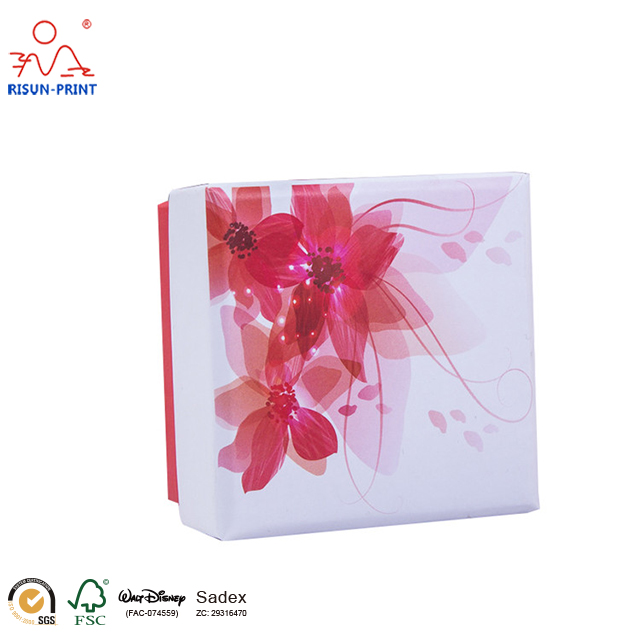

Color box refers to the folding carton and color thin corrugated box made of cardboard and corrugated board. It has the characteristics of light weight, portability, wide sources of raw materials, environmental protection and exquisite printing. At present, in the world, especially in developed countries, the definition of "color box" packaging is very clear. Paper box packaging including food, alcohol, medicine, daily use / cosmetics, tobacco, electronic products, etc. belongs to the category of "color box" packaging.Generally, it is used as a middle-grade color box packaging method, which is between the inner packing and the outer packing. As the name suggests, color boxes are usually made up of several colors, giving people a strong visual sense, so that buyers and users have a little understanding of the overall appearance and color of the goods. It is especially suitable for goods that can't be opened before purchase.

A color box production process can be divided into three steps: pre press, in print and post press.

Pre printing: refers to the work of the color box printing in the early stage, generally refers to design, production, typesetting, and film production;

1. The design stage is mainly completed by you, the designer and the printing factory. First of all, you can design the packaging and printing documents with the design company or advertising company you cooperate with according to your own requirements. Our designers will also give professional opinions to assist in the selection of packaging materials.

2. Film is the transparent film that transfers electronic documents through Imagesetter, which is used for printing and plate burning.

Send the design documents to our printing plant, and the film will be produced by our printing plant and film company. After the film is released, the printing is determined according to the film size, paper thickness and printing color.

3. Making knife mold and mounting pit production, the knife mold needs to be determined according to the template and the printed semi-finished product. A good knife mold determines the exquisite and perfect appearance of the color box. Mounting pit is mainly used in the pit box. Select different pit paper according to your requirements and stick it together by special machinery.

In printing: refers to the work in the middle stage of color box packaging and printing, and the process of printing finished products by printing machine;

After printing: refers to the post-processing work of color box packaging and printing, generally refers to the post-processing process of color box, including laminating, cutting, die cutting, gluing box, etc.

1. Printing appearance treatment is mainly to process and beautify the surface of color box, covering film, hot stamping, UV,varnishing and other processes.

2. Molding machine, tool mold. Make the color box die cutting to form the basic style of the color box.

3. Gluing the box is to glue the parts of the color box that need to be fixed and connected according to the template or design style. Through the above process, a color box production is completed.Websit:www.risunprint.com Contact: cathy Mobile / Whatsapp: +86 17875315636 Skype:+86 15626183287 Email: cathy@risun-print.com