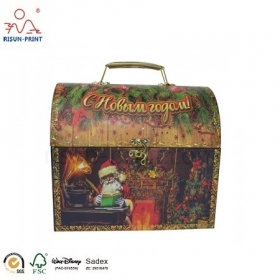

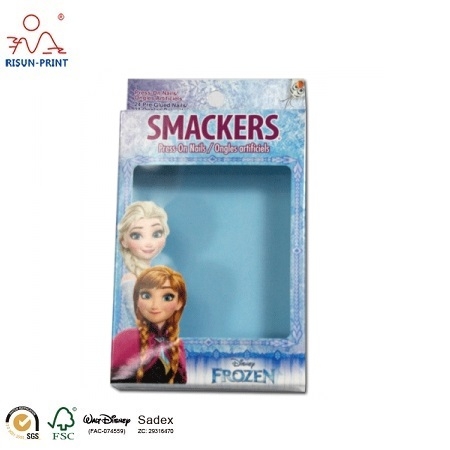

custom corrugated box supplier

Product Name

custom corrugated box supplier

Type

corrugated box

Materials

Single Sided Coated Paper、Corrugated Paper

Inser/Accessories

Surface Finishing

Four Color Printing、Spot Color Printing、Matt Lamination

Box Structure

corrugated box

Industry Use

Gift, Wine, Cosmetic, Perfume, Garments, Jewelry, PersonalCare, Electronic, Entertainment, Display etc

Payment

Single Sided Coated Paper、Matt Lamination、Corrugated Paper

T/T 40% In Advance

In the daily chemicals market, corrugated packaging boxes serve as a crucial packaging form, undertaking the significant responsibility of protecting products. The production process of corrugated packaging boxes is a complex and meticulous one, primarily encompassing the following steps:

-

Design and Drafting:

Utilizing design software such as Adobe Illustrator, CorelDRAW, and Adobe Photoshop, create design drawings for the corrugated packaging boxes, ensuring that they are both aesthetically pleasing and meet the product protection requirements. During the design process, factors such as product size, shape, weight, as well as potential risks during transportation and storage are taken into consideration to produce design drawings that meet customer specifications. -

Material Preparation:

Select high-quality corrugated cardboard and determine the appropriate number of layers based on design needs. Prepare materials required for printing, such as paper and ink, to ensure that the printing effect aligns with design specifications. -

Plate Making and Printing:

Produce plates based on the design drawings and select the appropriate printing method to guarantee the desired printing effect. -

Adhesive Forming and Assembly:

This process involves folding, creasing, and other procedures to ensure that the packaging box has a stable structure, an appealing appearance, and can be folded into shape for convenient use. -

Quality Inspection and Packaging:

Conduct quality inspections on the finished products to ensure they are flawless, intact, and meet customer requirements. During the quality inspection process, indicators such as box size, shape, printing quality, and adhesive strength are examined to guarantee product quality. Finally, the products are packed and prepared for loading and shipment.

Corrugated boxes exhibit excellent compression resistance, shock resistance, and tear resistance, effectively safeguarding daily chemicals from damage during transportation and storage. Furthermore, they can cater to the packaging requirements of diverse products through the design of various structures and shapes.

FAQ

Q: What types of custom packaging do you offer?

A: We offer a wide range of custom packaging solutions, including whiskey boxes, mooncake boxes, tea packaging, 3C electronics packaging, cosmetic boxes, luxury gift boxes, folding boxes, health product boxes, and various other premium packaging options tailored to meet diverse industry needs.

Q: What’s the MOQ?

A: The MOQ is 1000 units.

Q: What is your production capacity?

A: Our production lines are highly efficient and flexible, and can meet orders from small batches to large quantities.

Q: Do you provide design services?

A: Yes, our design services are primarily focused on structural design. We offer structural evaluation, optimization, and testing for your designs, and also provide auxiliary graphic design services when needed.

Q: What should I do if there is something wrong with the package I receive?

A: Before shipment, we implement a strict quality control process that includes thorough inspections and random checks. If you encounter any quality issues upon receiving the product, please contact our customer service team immediately. We will address the issue promptly and provide appropriate solutions.

Q: How to get a quote?

A: You can fill out the quotation request form on our official website, or contact us via email. Additionally, you can reach us through WhatsApp or WeChat for a quicker response. Please provide details such as packaging type, size, quantity, materials, and printing requirements so we can give you an accurate quote.

Q: Is there any charge for custom-packaged samples?

A: We provide sample production services, and the sample fee is based on specific needs. If you place a large quantity order, the sample fee can be deducted from the total order amount.

Q: Are your customized packaging materials environmentally friendly?

A: We are committed to environmentally friendly packaging and offer a variety of eco-friendly material options, including recyclable paper, biodegradable plastics and more.

Q: How to ensure product quality?

A: We have a strict quality control process in place, from raw material procurement to production and shipment. Every stage undergoes thorough inspection and testing to ensure that the products meet high-quality standards and requirements.

Q: How is shipping and delivery arranged?

A: We partner with multiple logistics companies to offer flexible shipping and delivery options. Whether for domestic or international shipping, we can arrange the most suitable logistics service to meet your needs.

Q: What should I do if there is something wrong with the package I receive?

A: Before shipment, we implement a strict quality control process that includes thorough inspections and random checks. If you encounter any quality issues upon receiving the product, please contact our customer service team immediately. We will address the issue promptly and provide appropriate solutions.

en

en fr

fr es

es

+86-13928758822

+86-13928758822 Sales@risunpackaging.com

Sales@risunpackaging.com